Description

Outline

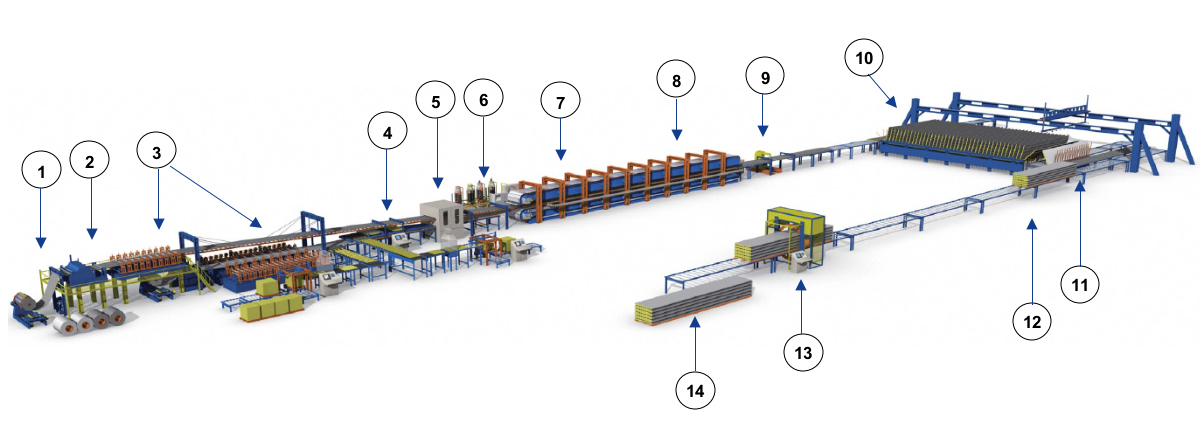

PU Sandwith Panel Production Line

– Space for installation : 50m × 120m 2 Lines (Office & Stock Area)

– Production Specification : Max Thickness 50 ~ 200mm, Width 1,000mm

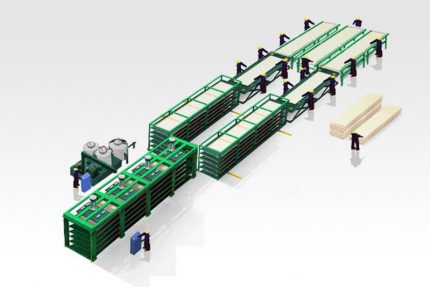

– Production Speed : 3~7m/min

– Supplying Raw Material

- Storage Tank : 1 x Polyol 2 ton + 1 x Cyclo pentane 1 ton

- Daily Tank : 1 x Polyol 1 ton + 1 x MDI 1 ton

- Working Tank : 1 x Polyol 0.5 ton + 1 x MDI 0.5 ton

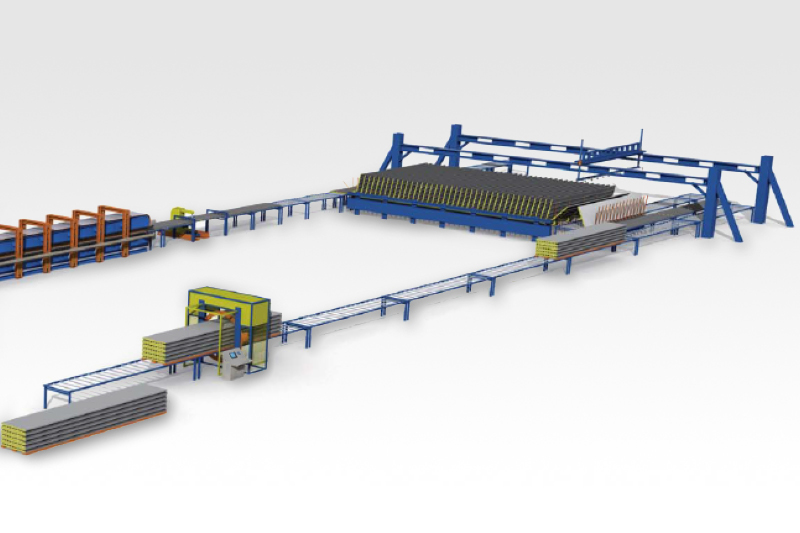

– Deck Floor Roll Forming, Double Belt Press Conveyer, Cutting & Cooling Line

– Auto Stacker & Wrapping.

– Anti Explosion System (Ex-Proof Motor, Ventilation ,Alarm & Monitoring System)

| No | DEVICE NAME | Q’ty | No | DEVICE NAME | Q’ty |

|---|---|---|---|---|---|

| 1 | Uncoiler system |

– 2-

|

8 | Heating system |

-1-

|

| 2 | Plastic film coating device |

-1-

|

9 | Saw cutter |

-1-

|

| 3 | Roll forming machine |

-1-

|

10 | Cooler for pu sandwich panel |

-1-

|

| 4 | Slitting machine |

-1-

|

11 | Turn over device |

-1-

|

| 5 | Preheating room |

-1-

|

12 | Auto stacking |

-1-

|

| 6 | High pressure pu foaming machine |

-1-

|

13 | Wrapping machine |

-1-

|

| 7 | Double belt press conveyor |

-1-

|

14 | Out Going (Moving Stock area) |

-1-

|

| NO | Description | Q’Ty | Specification | Remarks |

|---|---|---|---|---|

| 1 | Uncoiler system |

-2-

|

6~8m/min, Wide 1,500mm | Coil Car 2 Set |

| 2 | Plastic film coating device |

-1-

|

6~8m/min | With Film Cutter |

| 3 | Roll forming machine |

-1-

|

6~8m/min | |

| 4 | Slitting machine |

-1-

|

6~8m/min, Wide 1,200mm | |

| 5 | Preheating room |

-1-

|

200 M^2/min | Heat Exchager 300℃ |

| 6 | High pressure pu foaming machine |

-1-

|

High pressure | |

| 7 | Double belt press conveyor |

-1-

|

Conveyor length 24m | |

| 8 | Heating system |

-1-

|

Temp 70℃ | |

| 9 | Saw cutter |

-1-

|

Max Cutting length 12m | With Vent system |

| 10 | Roller for PU sandwich panel |

-1-

|

Roller Set Q’ty 25pcs | Roller Conveyor |

| 11 | Turn over device |

-1-

|

Max length 12m | |

| 12 | Auto stacking |

-1-

|

Vacuum Pad | |

| 13 | Wrapping machine |

-1-

|

Film 17~50㎛ | |

| 14 | Out Going (Moving Stock area) |

-1-

|

Fork Lifter |

Reviews

There are no reviews yet.