Description

Lay Out

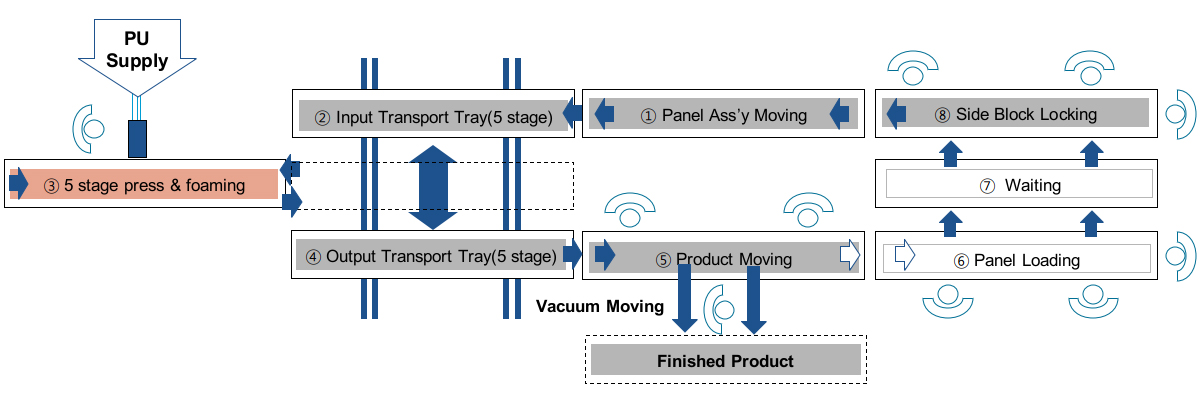

Concept

– Products : Max Length 8,000mm, Thickness 100mm, Width 1,250mm

– Production Speed : 10 Sheets/Hour

– 5 stage press foaming line

- Working table 3 set, Up/Down lifter 2 set, Moving carrier 2 set, 5 stage foaming press 1 set

- Moving Mould 13 set(Panel base)

- Overhead unloading manipulator(vacuum pad manual operation)

- High pressure mixing head & Carrier system 1 Set

5 stage Foaming Line

| Process Name | Process Description | Remark |

|---|---|---|

| ① Panel assembly ready | ② moves to the ready product from the ⑥~⑧ | Up/down lift |

| ② 5 stage carrier (loading) | Loaded in ③ Press | Moving Panel In/out |

| ③ 5 stage press & Foaming | Pressing and PU injection | |

| ④ 5 stage carrier (unloading) | Received once the moves one by one in the ③ to ⑤ | |

| ⑤ Product moving & Base Cleaning | Move ⓑ to the stock area the product in ④, and surface cleaning of the base | Up/down lift |

| ⑥ Lower/Upper panel input | Go to the lower & Upper panel and fixed base operations conducted | Roller Conveyor Moving |

| ⑦ Working & waiting | Panel Waiting | |

| ⑧ Side Block Locking | Fixed panel with side block |

Reviews

There are no reviews yet.