SUMMARY

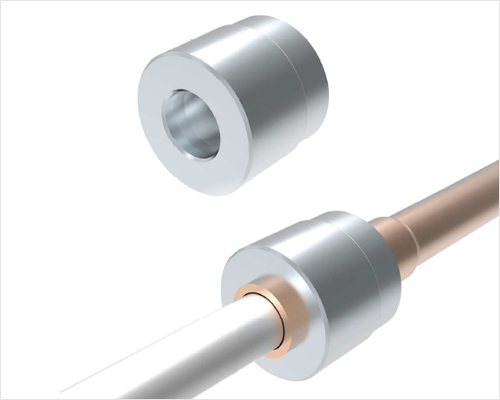

Lock Sleeve Technology

THE LOCK SLEEVE TECHNOLOGY was developed to compensate the disadvantages of existing brazing. It is a method of permanently sealing and connecting

metal refrigerant lines without brazing. It is fastened in the direction opposite to the assembly direction of the outer tube and the inner tube. This maintains

a permanent seal from gas leakage at the connection.

BRAZING

- Shrinkage or deformation caused by heat.

- No accurate quality inspection for internal defects.

- Cause of clogging by internal soot.

- Quality is fluctuate by different worker.

- Safety measures required about high temperature heat and hazardous gas.

- Narrow space operation is not possible.

- High manufacturing costs, according to the increase in Ag raw materials.

LOCK SLEEVE

- Easy for heterogeneous metal joint.

- No deformation of pipe, no leakage test required.

- No need for skilled operator (skilled within 1 hour).

- No safety measures required about heat and gas.

- Cost reduction (expenses, labor costs).

- Possible to Works in a narrow space.

- Utility unnecessary such as gas and pipe etc.

REFRIGERATOR APPLICATION

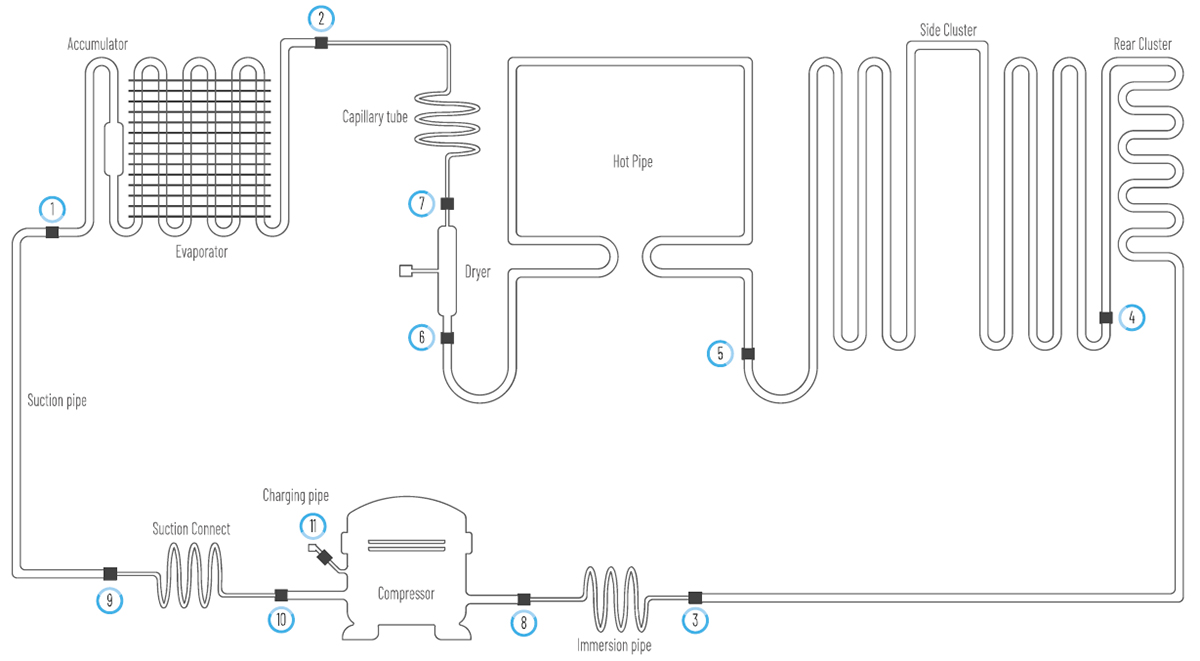

REFRIGERATORS & FREEZERS

THE REFRIGERATOR AND FREEZER CYCLE SYSTEMS consist of four parts: Evaporator, Condenser, Dryer and Compressor. The cycle diagram below

shows 11 Lock Sleeves with No Forst Model. Since the cycle system is the heart of every refrigerator, it can be said that each joint is important

in terms of operability, reliability and overall performance of the refrigerator.

EVAPORATOR SECTION

② Capillary Tube to Evaporator

CONDENSER SECTION

① Immersion pipe to Rear Cluster pipe

② Rear Cluster pipe to Side Cluster pipe

③ Side Cluster pipe to Hot pipe

DRYER SECTION

① Hot pipe to Dryer

② Dryer to Capillary tube

COMPRESSOR SECTION

① Compressorto Immersion pipe

② Suction pipe to Suction connect pipe

③ Suction connect pipe to Compressor

④ Compressor to Charging pipe