Description

REFRIGERANT ACCUMULATORS

– The hydropneumatic accumulator is a device designed specifically for the storage of liquids under pressure. As liquids are, for all practical purposes, incompressible, the objective is achieved by utilising the compressibility of gases.

– The accumulators can be conveniently used in different applications, of which the main ones are

- Reserve liquid under pressure, to temporarily maintain high levels of flow rate

- Stabilizer of pressurized lines, to limit the fluctuations for thermal changes or the flow rate

- Energy reserve in the form of pressurized fluid or hydraulic spring

- Absorber hammering or pulsation of the fluid

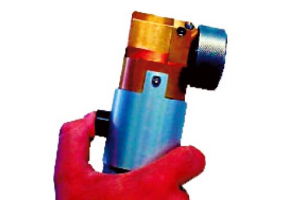

REFRIGERANT FILLER

The injector is the connection device beteen the Refrigerant charging machine and the cooler refrigerant circuit. Its characteristics are very important and variable according to the refrigerant charging unit characteristics that depend on the production assembly line.

FULLFILLER

- vacuum and charging injector with pneumatic/electromagnetic control, which minimizes any dead spaces

to ensure the maximum compactness and the entire transfer towards the group circuit in the cooling fluid

computed from the charging station. - The pneumatic needle valve and automatic connection to the unit to be processed are 1/4 “or 3/8” Hansen (ISO 7241B)

- It’s suitable for DEMPO, ROCKALL HC, ETNA and ROCKALL CO2 model.

ISSOFILLER

- It’s fully pneumatic controlled injector.

- The vacuum valve, the refrigerant valve and the needle are pneumatic operated.

- Connection by 1/4″ or 3/8″ Hansen Quick Coupler, 1/4″ SAE Quick Coupler Schrader Valve, Standard hose length 3.3M.

- It’s suitable for ROCKALL JR, ROCKALL, ROCKALL HS 및 DEMPO AC model.

VORTFILLER

- It’s electromagnetic piloted, this to control vacuum and refrigerant cartrige on the valve.

- Connection by 1/4″ Hansen Quick Connector or 1/4″ SAE Schrader Valve, Standard hose length 2.5M.

- It’s suitable for TEIDE TTD, ROCKALL JR model.

RTP (Refrigerant Transfer Pump)

Booster pump for the transferring of HC, HFC, HCFC refrigerant.

– Refrigerant Pressure R134a : Approximately 18 bar, R404A : Approximately 22 bar

– RTP needs aroung 5 bar air for operation and it’s adjusted by built in regulater.

Refrigerant pressure can be adjusted within the range of 10~25 bar.

| PROVISION | RTP6310 | RTP6315 RTP6315-HC |

RTP6325T RTP6325-HC |

|---|---|---|---|

| Maximum Rate | 3.6 L/min | 6.0 L/min | 13.0 L/min |

| Dimensions | 340x200x340 mm | 540x200x350 mm | 1100x200x400 mm |

| Weight | 15Kg | 17Kg | 40Kg |

| Refrigerant Type | HFC | RTP6315, RTP6325T : HFC, HCFC RTP6315-HC, RTP6325T-HC : HC, HFC, HCFC |

|

| Hydraulic Cylinder | 1 | 1 | 2 |

| Geometrical Multplier Ratio | 4.27 | ||

| Integrated Safety Valve Setting | 4000 kPA | ||

| Inlet Line | 1/2″ GAS-M | ||

| Suction Line | 3/4″ GAS-M | ||

| Compressed Air | Dried, Filtered, Not Lubricated | ||

| Air Pressure | 2~6 Bar | ||

Vacuum Pump

Edwards E2M28

(38,7 m3/h at 60 Hz)

| Description | Unit | MVP6 | MVP12 | MVP24 | MVP36 | MVP60 | MVP90 | |

|---|---|---|---|---|---|---|---|---|

| Displacement speed | 60Hz | m²/h | 6 | 12 | 24 | 36 | 60 | 90 |

| L/min | 100 | 200 | 400 | 600 | 1000 | 1500 | ||

| 50Hz | m²/h | 5 | 10 | 20 | 30 | 50 | 75 | |

| L/min | 80 | 170 | 335 | 500 | 830 | 1250 | ||

| Ultimate pressure | Gas ballast C | Torr | 5×10-4 | |||||

| Gas ballast Ⅰ | Torr | 5×10-3 | ||||||

| Gas ballast Ⅱ | Torr | 5×10-2 | ||||||

| Water vapour tolerance | Torr | 40 | 40 | 25 | 25 | 40 | 40 | |

| Oil filling | L | 2:24 | 1.1 | 2 | 2.3 | 4.5 | 6.5 | |

| Inlet port | DN | 25kF | 40kF | |||||

| Outlet port | DN | 25kF | 40kF | |||||

| Motor power | kw | 0.4 | 0.75 | 1.5 | 22 | |||

| Rotational speed of pump | 60Hz | R.P.M | 1750 | |||||

| 50Hz | R.P.M | 1450 | ||||||

| Noise Level(without gas ballast) | dB | 50 | 50 | 52 | 52 | 56 | 56 | |

| Weight | kg | 21 | 22.5 | 38 | 41 | 68 | 84 | |

Reviews

There are no reviews yet.