Description

| CONFIGURATION OF MACHINE | UNIT | CAPA |

|---|---|---|

| TANK UNIT | ||

| Tank Capacity (each) | ||

| Tank Capacity (each) | liter | 50-2000 |

| Working Pressure | bar | 3~4 |

| Components Temperature | °C | 20±2 |

| Stirrer Motor Power | hp | 1.5 |

| DOSING/METERING UNIT | ||

| Metering Pump A2VK, A7VK Series | cc | 12-107 |

| Pump Feeding Motor Power | kw | 8.4-77.8 |

| Minimum Machine Total Output | gr/sec | 40 |

| Maximum Machine Total Output | gr/sec | 3,200 |

| Max. Components Output Pressure | bar | 220 |

| Flow Metering | bar | 350 |

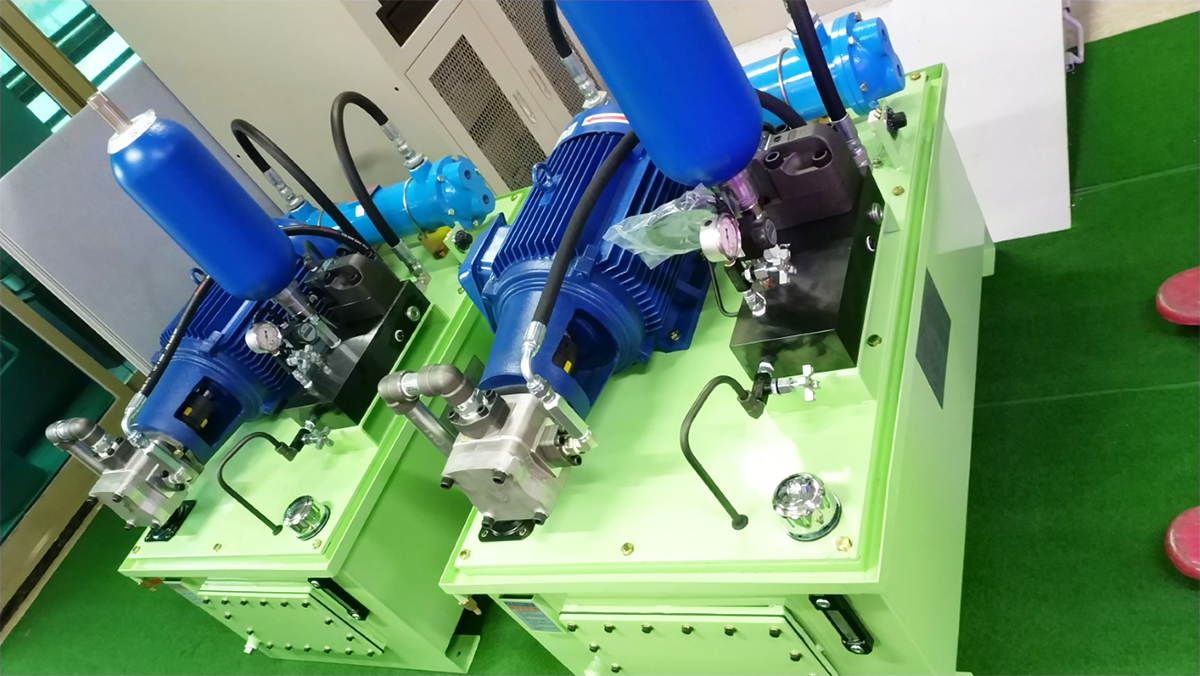

| HYDRAULIC UNIT | ||

| Tank Capacity | liter | 120-500 |

| Pump Output | lit/min | 14-70 |

| Motor Power | kw | 5.5-22 |

| Working Pressure | bar | 200 |

| Accumulator Capacity | liter | 6 |

| CONTROL UNIT | ||

| PLC | Mitsubishi, Siemens, LS | |

| Touch Screen | Pro-Face | |

| Pneumatic Components | SMC | |

| Hydraulic Components | Nachi, Yuken | |

| Electric Motor | – | |

| OTHER DETAILS | ||

| Total Installed Power | kw | – |

| Total Machine Weight | kg | – |

TANK UNIT

- Working Tank : SUS Material, Test Pressure 10Bar, Working Pressure 3.5Bar

- Volume : 50L ~ 2000L, Insulated by Al film jacket, Spiral coil for optimal cooling effeciency.

- Pressure Switch, Safety Valve

- Heat exchanger on the return line

- Auto level display(4 Points)

- Inspection window on the top of tank

- Agitator for POL/ISO tank(Magnetic Coupler Type)

- Drip Pan

METERING UNIT

- Axial Piston Pump for POL & MDI(12cc~127cc/Rotation), Manual Hand Wheel for adjusting output

- Inver type driving motor(Ex-Proof)

- Magnet coupler with Conversion Kit

- High/Low digital pressure switch

- Pressure relief valve, 250 Bar Bypass

- Edge Filter

- Drip Pan

HYDRAULIC UNIT

- Hydraulic Oil Tank(150~500L), Nachi Pump, AC Motor

- Level gauge, Thermometer

- Manual plug, Filter on the inlet and return line

- Cylinder type heat exchanger

- Accumulator 100L- Pressure switch

- Pressure adjusting valve, Safety valve

CONTROL UNIT

- PLC (Mitsubishi, Siemens, LS), Touch Screen(Pro-Face, LS)

- Start/Stop for Hydraulic Oil Pump, POL & ISO Pump, Agitator

- Emergency stop button

- Setting POL, ISO temperature range

- Displaying program parameter

- Selection of Auto/manual mode

- Alarm Display

- 3 color light on the top of the control panel

COOLING UNIT

| Provision | 3RT | 5RT | 7.5RT | 10RT | 15RT | 20RT | 30RT | 40RT |

|---|---|---|---|---|---|---|---|---|

| Cooling Capacity(Kcal/hr) | 8,400 | 14,000 | 21,000 | 28,000 | 42,000 | 56,000 | 84,000 | 112,000 |

| Temperature Range(°C) | 5~30 | |||||||

| Ambient Temperature Range(°C) | Within 0~45 | |||||||

| Cooling Water Pressure Range(kgf/cm²) | 1.5~3.5 | 1.5~3.5 | 1.5~3.5 | 1.5~3.5 | 2.2~3.5 | 2.2~3.5 | 2.4~3.9 | 2.4~3.9 |

| Cooling Water Circulation Volume Range(LPM) | 15~65 | 15~65 | 30~130 | 30~130 | 100~200 | 100~200 | 160~460 | 160~460 |

| Cooling Water Tank Capacity(Liter) | 50 | 70 | 100 | 135 | 165 | 280 | 350 | 500 |

| Cooling Water Link Pipe(A) | 20 | 25 | 32 | 32 | 40 | 40 | 50 | 65 |

| Refrigerant | Freon R-22, 407C | |||||||

| COMP Capacity(Kw) | 2.25 | 3.75 | 5.63 | 7.5 | 11.25 | 15 | 22.5 | 30 |

| Circulation Pump Capacity(Kw) | 0.75 | 0.75 | 1.29 | 1.29 | 2.1 | 2.1 | 3 | 3 |

| Cooling Fan Motor Capacity(Kw) | 0.185 | 0.3 | 0.78 | 02×2 | 0.4×2 | 0.75×2 | 0.75×3 | 0.75×3 |

| Power Consumption(Kw) | 3.2 | 4.8 | 7.7 | 9.2 | 14.2 | 18.6 | 28 | 35.25 |

| Power | AC 220/380/440V 3P 50/60Hz | |||||||

| Control Circuit Power | AC 220V 1P | |||||||

| External Dimension(W x L x H) | 600×1000 x1000 |

700×1100 X1100 |

760×1300 x1400 |

800×1500 x1400 |

900×1800 x1700 |

1000×2000 x1750 |

1000×2900 x1800 |

1100×3200 x1950 |

MIXING UNIT

- High pressure flexible hose(Parker)

- Laminar flow for pouring into Open/Close Mold

- 3way rotary valve for recycling and mixing position

- Self cleaning plunger

- POL/ISO nozzle

- Proximity sensor for controlling M/C & Cleaning piston

- Double tilted injection nozzle for maximum mixing efficiency

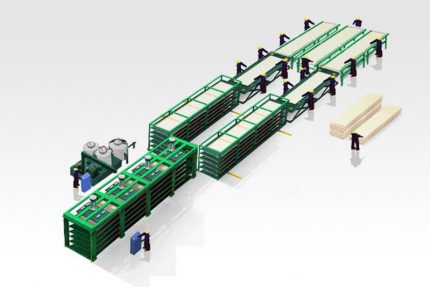

VIDEO

Refrigerator Cabinet PU Foaming Line – Model Change

FSR Door Foaming Line

Door Foaming Line

Cabinet Foaming Line

Reviews

There are no reviews yet.