Description

| CONFIGURATION OF MACHINE | UNIT | CAPA |

|---|---|---|

| TANK UNIT | ||

| Tank Capacity(each) | liter | 50-2000 |

| Working Pressure | bar | 3~4 |

| Components Temperature | ˚C | 20±2 |

| MC CLEANING SYSTEM | ||

| Tank Capacity | liter | 20 |

| Working Pressure | bar | 1.5 |

| DOSING/METERING UNIT | ||

| Pump Type | Gear Pump | |

| Maximum Setting Pressure | bar | 40 |

| Total Output | gr/sec | 25~5000 |

| CONTROL UNIT | ||

| PLC | Mitsubishi, Siemens, LS | |

| Touch Screen | – | |

| Controlling Pressure, Temperature, Cooling, Heating | – | |

| MIXING UNIT | ||

| Mixing | By Stirring Motor | |

| Operating | By OP Box | |

| Auto/Manual Selection | – |

TANK UNIT

- Working Tank : Carbon Steel Material Cover(SUS Inside)

- Single Jacket

- Working Pressure : 3.5 Bar

- Safety Valve for Water Jacket : 2.5 Bar

- Level Gauge : Transparent Tube

- Temperature Sensor : PT100

MC CLEANING SYSTEM

- 20L Volume MC Storage Tank equipped with Air Regulator and Level Gauge

- Electro Valve for Controlling Cleaning

- Cleaning time controlled by PLC

- Cleaning Pressure 1.5 Bar

- Agitator works simultaneously with MC cleaning

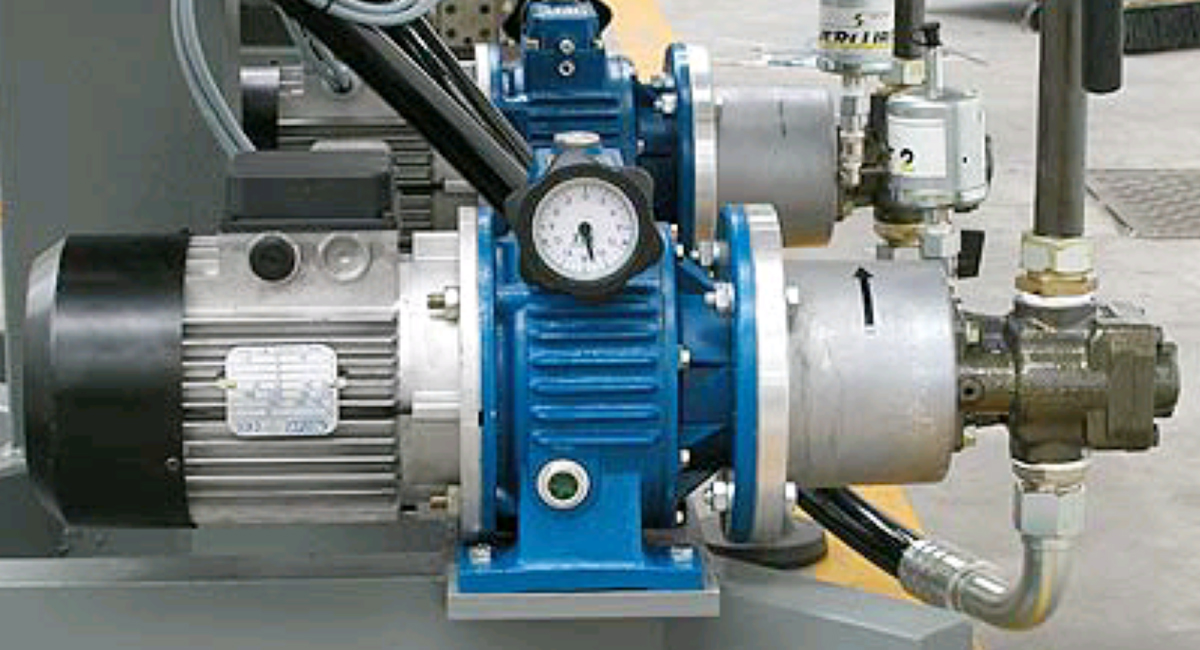

METERING UNIT

- High Precision Gear Pump, No Leakage

- Setting Pressure Max 40 Bar

- Adjusting Pumping Output & Ratio by Independent System

- Inverter Type Control

MESH FILTER

- Before the Entrance of Pump

- 330㎛

CONTROL UNIT

- Touch Screen for Machine Operation and Each Unit Setting.

- Pressure Controller

- Temperature Controller

- Cooling/Heating Line Control

- Emergency Stop

- Reset

MIXING UNIT

- Mechanical Mixing by Stirring Motor

- 3 Stage Speed Control by Belt Pulley

- Auto/Manual Agitation

- Head Open/Close by Air Cylinder

- Use Friendly Operation Box on the Head

VIDEO

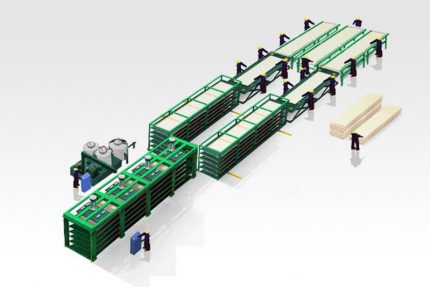

Refrigerator Cabinet PU Foaming Line – Model Change

FSR Door Foaming Line

Door Foaming Line

Cabinet Foaming Line

Reviews

There are no reviews yet.